This website uses cookies to improve the navigation experience of the users.

We use only technical cookies; we don't use profiling cookies.

You can check the details by checking our privacy policy here.

If you continue on the website you accept the use of cookies; alternatively, you can leave the website.

We use cookies to improve your experience on this website. If you continue your navigation, it means you accept to use them. To obtain further information, or to learn how to chnage the current configuration, please click on the button on the left.

latest news!

Meet our newest associate:

Wilbert Smith

See Who We Are

Go to the Who’s Who page to meet us!

check what we do

Sensing As A Service (SAAS)

Successful operations rely on the timely acquisition, transmission and processing of data, which must be immediately converted into knowledge for useful action. This same Data Sensing & Integration for Real Time Networking and Analysis will shrink the world/universe through preventive networking. This will have a profound effect on everything that touches our lives.

Read more...

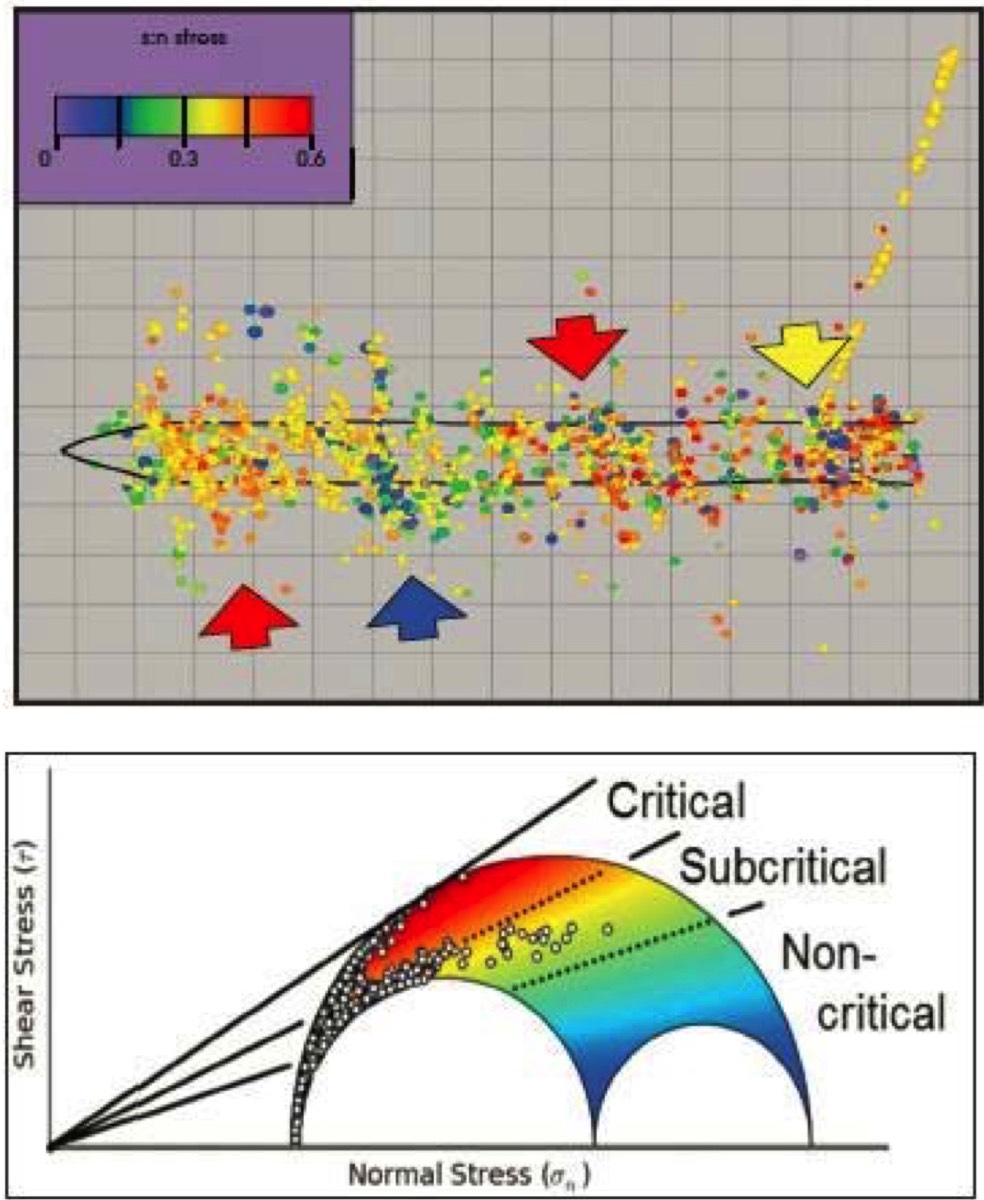

Non Destructive Testing

Nondestructive Testing (NDT) is the development and application of technical methods to examine materials or components in ways that do not impair future usefulness and serviceability in order to detect, locate, measure and evaluate flaws; to assess integrity, properties and composition; and to measure geometrical characteristics.

Read more...

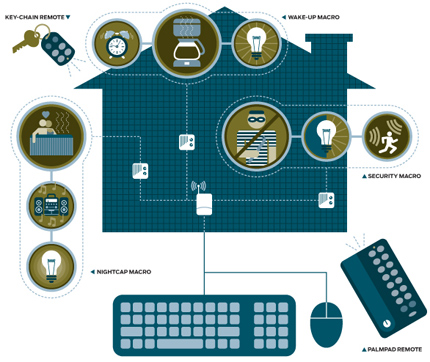

The Smart Technology

Smart Technology consists of a custom kit which utilizes both high-end hardware and software packages. When designed and interfaced it provides a client the ability to monitor and control events and devices within a residence or commercial building.

Read more...

The Smart Factory

As technology advances, the smart factory is developing its own path by full automation redesign. Smart factory technology allows large amounts of data to be communicated via actuators and sensors from the production floor to the control room…

Read more...

Eagle Technology Inc. and i-pag Consulting Form a Business Alliance to Better Serve the Manufacturing Sector

Eagle Technology Inc., a world leader in CMMS (Computerized Maintenance Management Software) and i-pag Consulting, the International Performance Alliance Group, have formed a business alliance in order to bring manufacturers an integrated tool set which promotes efficiency and cost reduction.

Read more...

Read Our Stories!

Go to the Our Stories page to see some examples of our successes!

WHY i-pag CONSULTING?

We are an International group of professional experts in Lean Manufacturing/Enterprise, Six Sigma, Total Quality, Operational Excellence, Logistics, Marketing and Sales, Transactional Office applications, Lean Health Care, Short and Long Term Strategies and Cultural Change Management Road Map development.

We can supply Information Technology - IT support for the above activities, NDT Non Destructive Testing as well as AS-9100 Aerospace, ISO-9000:2008 General, TS-16949 Automotive certifications.

Our Team has over 432 accumulative years, average of 27 years per consultants, worked for the top Fortune 500 Worldwide Companies. We are all experienced, hands-on practitioners, teachers/mentors, collaborative problem solvers and seasoned Executive Managers.

Our Team can work internationally in all countries world-wide.